Combi 302 Polar

Specifications & Technical Data

Combi 302 Polar is a ventilation unit with heat recovery that is typically used in large single-family dwellings.

Most of the time, the heat recovery process occurs via a high-efficiency counterflow heat exchanger that achieves 85 – 95% heat recovery. The unit is also equipped with an air to air heat pump that can heat the supply air when the dwelling requires heating. In some low energy houses Combi 302 Polar is the primary heat source, but it can also control external, supplementary heat sources such as electric radiators.

The heat pump has a reversible cooling circuit and it can therefore also cool the supply air with up to 14 ºC when necessary during the summer. Combi 302 Polar is not comparable with an air conditioner.

The cooling effect of the unit is not as substantial, which is due to its low level of air exchange of approx. 0.5 times/hour. But when the outdoor air is cooled down, it will condense, and the cooler air that is led into the dwelling is therefore less humid. Low air humidity makes it easier to cope with a high indoor temperature. We therefore call it “Comfort cooling”.

Combi 302 Polar is often installed in an unused loft so it does not take up space in the utility room. Placing it in the loft also means that it is easy to block potential noise from the unit and prevent it from entering the dwelling.

Airflow (see planning data for SEL/SFP values)

Min : 50 m3/h

Max : 375 m3/h

TECHNICAL DATA

| Dimensions (W x D x H) | 1300 x 580 x 700 mm |

| Weight | 83 kg |

| Plate type casing | Aluzinc steel plate, white powder coating RAL9016 |

| Heat exchanger type | Polyethylenterephthalat counterflow heat exchanger |

| Fan type | EC, constant volume |

| Filter class | Greencycle ISO Coarse > 75% (G4) |

| Compressor type | Piston compressor |

| Refrigerant | R134a |

| Refrigerant filling | 700 gr. |

| Duct connections | Ø160 mm |

| Condensate drain | PVC Ø20 x 1,5 mm |

| Supply voltage | 230V 50/60 Hz |

| Max. input/power | 1,2 kW / 5,2 A |

| Standby power | 3W |

| Tightness class | IP31 |

| Ambient temperature | -20 / +40 °C |

| External leakage | < 1,1 % (*1) |

| Internal leakage | < 1,8 % (*2) |

| Heat loss classification | T2 |

*1 – At ± 250 Pa and 300 m3/h according to EN 13141-7.

*2 – At ± 100 Pa and 300 m3/h according to EN 13141-7.

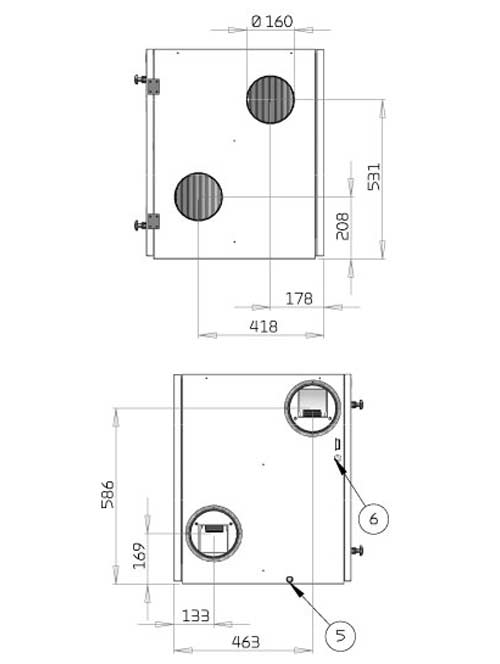

DIMENSIONS

All dimensions are in mm.

Connections

1: Fresh air

2: Supply air

3: Extract air

4: Discharge air

5: Condensate drain

6: Electric supply

INSTALLATION

ATTENTION! When positioning the unit, you should always consider future services and maintenance. It is recommended that you leave a minimum of 60 cm of clear space in front of the unit.

It must be easy to replace filters and it must be possible to replace, for instance, fans and other components.

ATTENTION! The unit must be level to enable proper drainage from the condensate tray.

The unit makes little noise and produces only weak vibrations, but you should still take into account potential vibrations that can spread from the unit to individual building components. In order to separate the unit from its foundation, it is therefore recommended that you install vibration absorbers under the unit. There should be approx. 10 mm distance to other building components and to permanent fixtures.

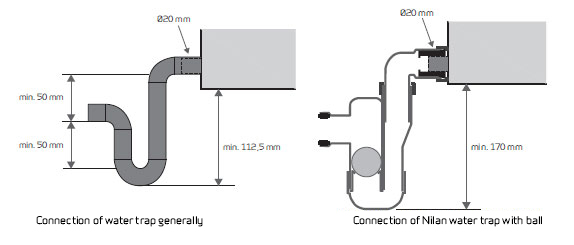

Condensate drain

ATTENTION! You MUST install a water trap in connection with the condensate drain to ensure that condensate water can drain away. If you set up the unit outside the climate screen, it is important to use a heating cable to prevent the condensate drain from icing up. Frost protection of the unit is the installer’s responsibility.

PLANNING DATA

Capacity

Capacity of standard unit as a function of qv and Pt, ext.

SEL values according to EN 13141-7 are for standard units with ISO Coarse >75% (G4) filters and without heating element.

SEL values comprise the unit´s total power comsumption incl. control.

Conversion factor: J/m³: 3600 = W/m³/h.

Attention! The SEL values are measured and stated as a total value for both fans.

Temperature efficiency

Temperature efficiency for units with counterflow heat exchanger according to EN308 (dry).

Temperature efficiency EN308: ɳt = (tsupply air-tfresh air)/(textract air-tfresh air)

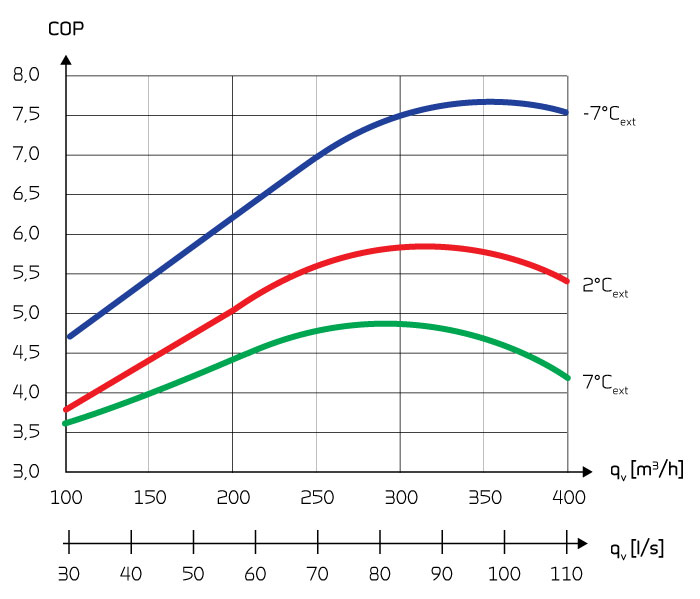

COP (heating)

Heat effect factor COP [-] supply air as function of outdoor temperature [°C] and volume flow qv [m3/h].

According to EN14511, extract air = 21°C.

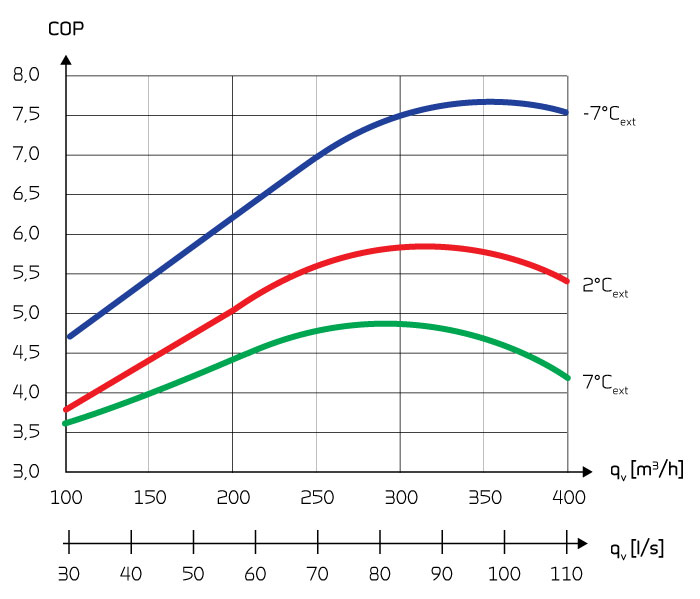

COP (heating)

Heat effect factor COP [-] supply air as function of outdoor temperature [°C] and volume flow qv [m3/h].

According to EN14511, extract air = 21°C.

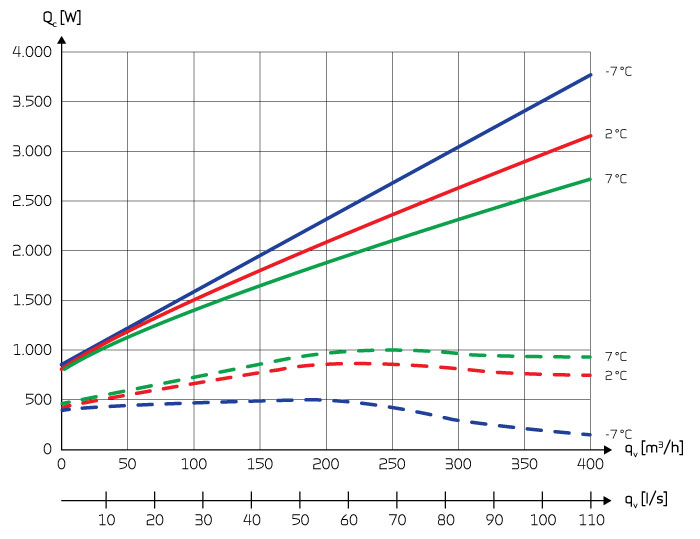

Heat effect (supply air)

Heat effect Qc [W] as a function of qv [m3/h] and fresh air temperature [°C].

According to EN 14511, extract air = 21 °C

The fixed curves indicate the total heat recovery at different outdoor temperatures, where the dotted line indicates the heat supplied to the supply air (heat output).

The difference between the fixed curves and the dashed curves corresponds to the ventilation loss covered by the heat pump and the heat exchanger.

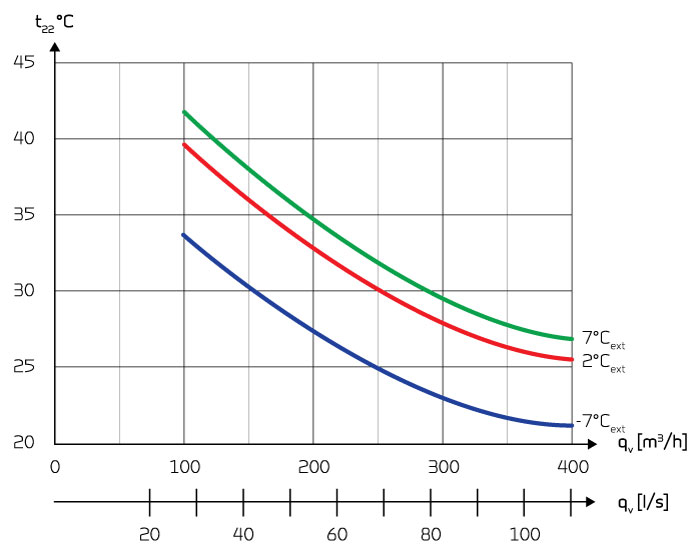

Supply air temperature (heating)

Supply air temperature [°C] as a function of fresh air temperature [°C] and volume flow qv [m3/h] balanced flow.

Extract air temperature = 21 [°C], 45 RH [%]

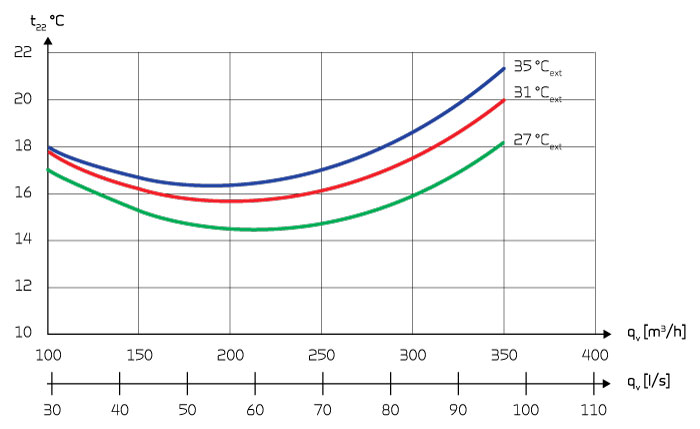

Supply air temperature (cooling)

Supply air temperature [°C] as a function of fresh air temperature [°C] and volume flow qv [m3/h] balanced flow.

Extract air temperature = 24°C

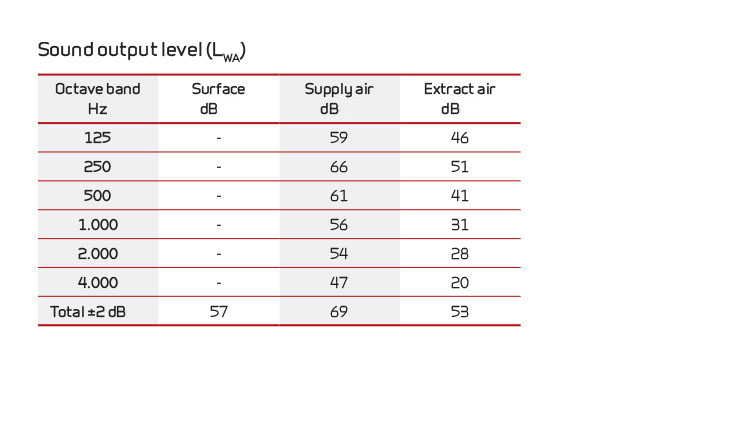

Sound data

Sound data for qV = 210 m3/h and Pt, ext = 100 Pa according to EN 9614-2 for surfaces and EN 5136 for ducts.

Sound output level LWA drops with falling air volume and falling back pressure.

Sound output level LpA at a given distance will depend on acoustic conditions in the place of installation.

AUTOMATION

The CTS602 control system is an advanced control system with many settings options. The control system is supplied with factory default settings that can be adapted to the operational requirements in order to achieve best possible operation and utilisation of the unit.

The HMI Touch panel provides an overview of the current operation of the unit, and the structure of its menu makes it easy to navigate for both user and installer. There is an option for selecting between 2 front page images for the main screen.

External communication

The CTS602i control unit communicates by default with Modbus RTU RS485 communication. A CTS system using this form of communication can easily be connected to the unit.

Functional overview CT602 control panel

CLICK TO VIEW

| Function overview | +Standard -Accessories |

|

| Filter guard | The time-controlled filter guard notifies you when it is time to change the filter. Can be set between 30 and 180 days. | + |

| Operating mode | Can be set to run Auto according to set values or set to run in heating or cooling mode. | + |

| Stepless regulation | The four ventilation stages can be set steplessly 20-100%, with different values for supply air and extract air. | + |

| Moisture management | Built-in humidity control can be set to run high ventilation mode when there is high humidity (when you are in the shower) and low ventilation mode if the humidity in the home becomes too low. | + |

| Active cooling | The unit can be set to cool the supply air in the summer if needed. When the heat pump cools, the heat is deposited in the hot water tank, so that you get “free” hot domestic water when the unit is in cooling mode. | + |

| Low outdoor temperature | It is possible to lower the ventilation when the outside temperature is low, to avoid that the humidity inside becomes too low. | + |

| CO2 management | It is possible to control the ventilation level according to the home’s CO2 level. | – |

| Temperature settings | The temperature settings are used by the controller to regulate the operation of the entire system. | + |

| Frost protection | The control has an automatic function for defrosting the heat exchanger if ice should form in it. | + |

| Frost protection Polar | The Polar model has a built-in anti-freeze pre-heater to protect the counter-flow heat exchanger so that it does not get ice. | + |

| Frost protection EHD | The control can control an EHD damper, which is used if the outside air comes via a roof hood. | + |

| Hot domestic water | Compact P produces the hot domestic water via the air/air heat pump in the ventilation part. | + |

| Pause domestic hot water | It is possible to pause hot water production if, for example, for a period not at home. In this way, energy is saved. | + |

| Antifreeze hot water | To protect the hot water tank, it is equipped with a frost protection function. | + |

| Electricity supplement hot water |

If the demand for hot water is so great during periods that the heat pump cannot keep up, an electric supplement can be switched on to help heat the hot domestic water. |

+ |

| Scalding protection | The control has a built-in scalding protection, which ensures that the hot domestic water does not become too hot and could scald the users. | + |

| Anti-Legionella | The control has an Anti-Legionella treatment of the hot domestic water, which can be activated manually or automatically. | + |

| Anode | Electronically monitored anode. Notifies when it’s time to replace it, extending the life of the hot water tank. | |

| SHW preheating tank | An additional hot water tank SHW can be connected to the GEO geothermal heat pump and preheat the hot domestic water to 45 ºC before it enters the Compact P hot water tank. | + |

| Hot domestic water | If the Compact P is ordered with a solar coil, the GEO ground source heat pump can be connected to the Compact P hot water tank and help produce the hot domestic water. A good solution if there is a large need for domestic hot water and there is no space for a SHW container. | + |

| Weekly schedule | A weekly plan can be made with different settings depending on the use of the home. | + |

| Smart Grid | Compact P GEO is approved for Smart Grid solutions, where the electricity company determines the electricity consumption and thus the operating costs. | + |

| User selection 1 | Used if you want to override the unit’s operation via a potential-free signal. Used e.g. if an extractor hood is connected to the system. | + |

| User choice 2 | Used as user selection 1, but at the same time has an output signal that can be used e.g. to control a damper. | + |

| Event log | Logs events in the control as well as error messages and warnings. | + |

| Read out data | All current values in the plant’s operation can be read out. Most often used for troubleshooting. | + |

| Emergency stop ventilation | You must not switch off the ventilation, as this can cause damage to the unit, duct system and, in the worst case, the home. But it may be necessary to briefly switch off the ventilation, e.g. due to an emergency notification. | + |

Further information about all the functions can be found in the unit’s Software and Assembly instructions.